Better performance and energy savings by HVAC & Chiller PRE-COOLING systems.

The misting systems are the solution ideal for cooling the HVAC condensers The air conditioning systems make to a minimum during hot summer days, just when they should give the best results. The ability to

cooling decreases of 14-15%, while the power demand increases up to 31%. The problem occurs with the capacitors that need to transform the vapors refrigerant to the liquid state, forcing air through the unit and

absorbing heat from the refrigerant, causing its condensation.

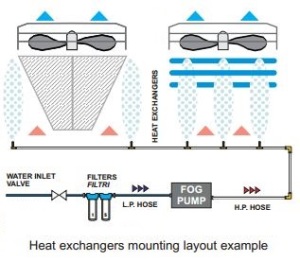

The use of a spray system water chillers cooled air can improve the efficiency of working conditions of the same, since the atomized water lowers the temperature the air entering the condenser.

The typical air-cooled chillers, a reduction in air temperature inside the condenser, of 6 ° C gives as result in an improvement of efficiency to the extent of 14%. In the case of a reduction of air temperature of 12 ° C, the improvement in efficiency would increase to 25-30%. Tests have shown that the power reduction of the absorption energy is feasible, although it depends on external factors, such example, the saturation level.

ADVANTAGES

-Reduction of up to 12 C temperature of the incoming air Reduction of energy consumption, at least 30%

-Increased efficiency HVAC units up to 30%

-The life cycle of the entire HVAC system extended

-Low costs

-fast and easy installation

CHILLER PRE-COOLING

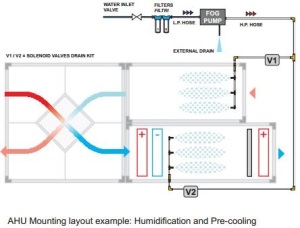

fogging systems are the best solution for chiller condenser cooling.chiller systems perform at Their worst in hot summer days, When They just are needed the most. The cooling capacity

decreases by 14-15% and the power draw Increases by 31%. The problem OCCURS in condensers Which Has to change vapors forcing liquid refrigerant into the air through the unit and absorbing

heat from the refrigerant causing it to condense. Applying water fogging system to air-cooled chillers can Improve the efficiency under most of the working conditions, as the water

mist could lower the air temperature entering the condenser.

On typical air-cooled chillers, a reduction in condenser air temperature of 6 ° C will result 14% improvement in efficiency and 12 ° C about 25-30%.

Tests have shown That this absorbing power reduction is achievable, Although it depends on external factors: such as saturation level.

BENEFITS

Air temperature outside the unit lowered by up to 12 C

Energy consumption decreased At, as much as 30%

Increase the efficiency of chiller units up to 30%

Live of the whole system extended

Low start up and operating costs

Quick installation